It has been quite a while without any updates. Life has changed a lot while I have been away. From starting a new job, in a better career, to moving back to my home state, and closer to the truck project. I have been both a lot more busy, but also making more frequent progress on things as I am closer to the project again.

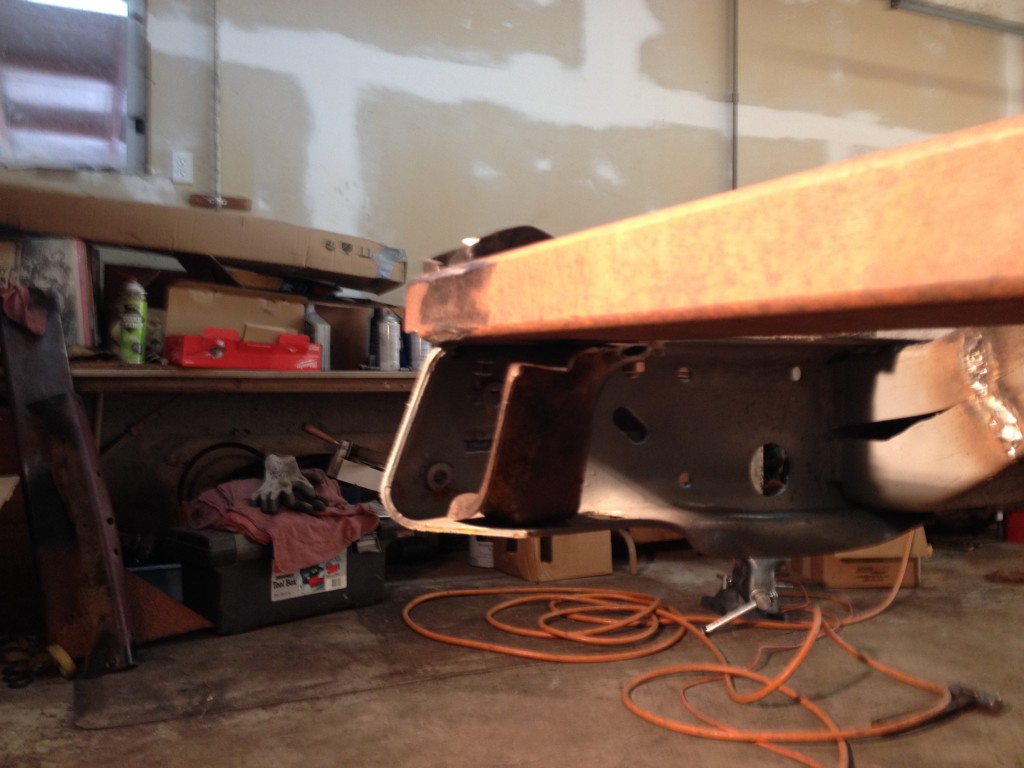

the first update is the fabrication around the power steering box. The frame has been fully boxed in, with adding in the inner frame spacer from a ’78 F-250 frame, with a plate closing off the inner side of the frame’s C channel to fully box in the frame where the steering box mounts to the frame. This has been done to strengthen the frame and provide a solid anchoring point for the push/pull of the steering with anticipated larger tires, moving at slow speed while crawling.

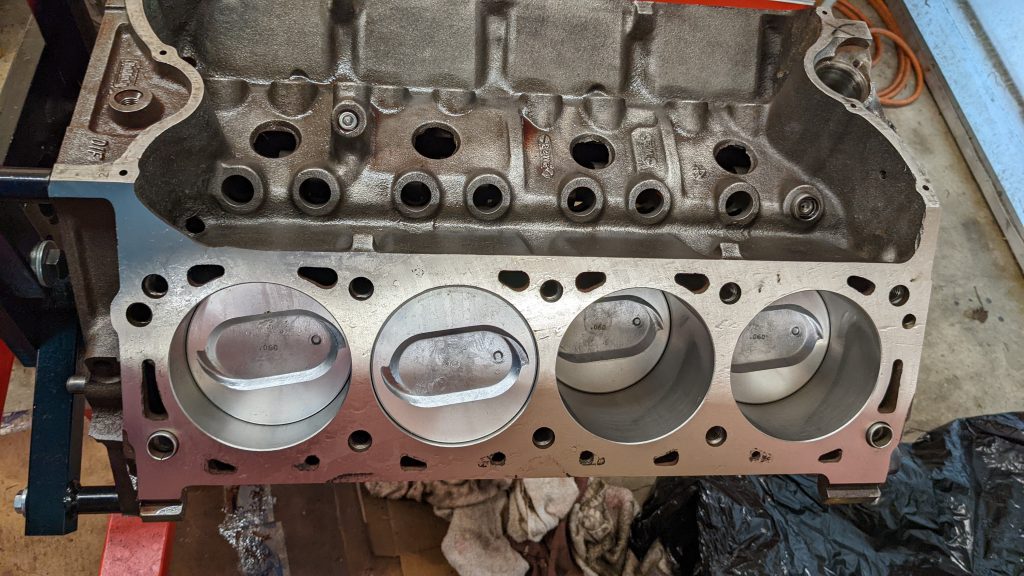

After that, we started working on the drivetrain. We are using a 73 Ford 460 engine with a C6 automatic transmission, mated to a married transfer case. The engine needed to be rebuilt. It had about 350,000 miles on it. This was all of it at it’s starting point, being used to set the engine mounts and crossmembers.

The engine had thrown a main bearing, and during tear down it was discovered that it was going to need machining work. We sent it out to Action Machine Shop in Shoreline Washington. The block was bored to .060 over, and once the machining was complete we built the engine up.

Unfortunately, we didn’t keep up with pictures throughout the engine build. We finished the short block, and rebuilt the heads. On the exhaust ports we ground down the Thermactor exhaust port bumps to improve airflow, and completed the engine assembly.

The transmission has also been rebuilt with new clutch disks and seals and a new torque converter. The transmission has a manual valve body and a shift kit in it, and in all the vehicles I have ever driven with an automatic, this transmission is the only one that i didn’t wish was a stick. If your not familiar with a shift kit, I would really recommend looking into them.

For the transfer case, I decided to go with the married NP-205 running a dual stick configuration. This will allow setting H-L-N on each axle independently, making the truck FWD, RWD, or 4WD on demand, as well as selecting Hi or Low range without engaging both axles. The transfer case has been modified with the shift rail kit, as well as cleaned, inspected, and all seals replaced.

This was shortly before the heads were finished. I will need to add more images soon. We have almost finished the accessory devices, and are also moving onto rebuilding the front axle currently. More updates to follow.